Isiqondiso Senqubo Yokukhiqiza ye-Leaf Springs

-I-tapering (i-tapering ende kanye ne-tapering efushane)(Ingxenye 3)

1. Incazelo:

Tapering/Rolling inqubo: Ukusebenzisa umshini wokugoqa ukuze unciphise imigoqo eyisicaba yentwasahlobo enogqinsi olulinganayo emigodleni yobukhulu obuhlukahlukene.

Ngokuvamile, kukhona izinqubo ezimbili tapering: inqubo eside tapering kanye short tapering inqubo. Uma ubude be-tapering bungaphezu kuka-300mm, kubizwa ngokuthi i-long tapering.

2. Isicelo:

Wonke amaqabunga entwasahlobo.

3.1. Ukuhlolwa ngaphambi kokutshala

Ngaphambi kokugoqa, hlola uphawu lokuhlola lokubhoboza (ukubhoboza) imbobo yesikhungo semigoqo ye-spring flat kwinqubo yangaphambilini, okumele ifaneleke; ngesikhathi esifanayo, qinisekisa ukuthi ukucaciswa kwamabha e-spring flat kuyahlangabezana yini nezidingo zenqubo yokugoqa, futhi inqubo yokugingqa ingaqalwa kuphela uma ihlangabezana nezidingo zenqubo.

3.2. Ukugunyazwa aumshini wokugoqa

Ngokwezidingo zenqubo yokugingqa, khetha indlela yomugqa oqondile noma i-parabolic rolling. Ukuqulwa kwecala kuzokwenziwa ngokumiswa kokugcina. Ngemuva kokuthi ukuqulwa kwecala sekuphumelele ukuzihlola, kuzohanjiswa kumhloli ukuze kubuyekezwe futhi kugunyazwe, bese ukugoqa okusemthethweni kungaqalwa. Ngokuvamile, kusukela ekuqaleni kwe-tapering kuya ekugoqeni izingcezu ezingu-20, kuyadingeka ukukhuthala ekuhloleni. Lapho ugoqa izingcezu ezingu-3-5, kuyadingeka ukuhlola usayizi wokugoqa kanye futhi ulungise umshini wokugoqa kanye. Ukuhlolwa okungahleliwe kungenziwa ngokulandela imvamisa ethile kuphela ngemuva kobude bokugoqa, ububanzi nokuqina kuzinzile futhi kufanelekile.

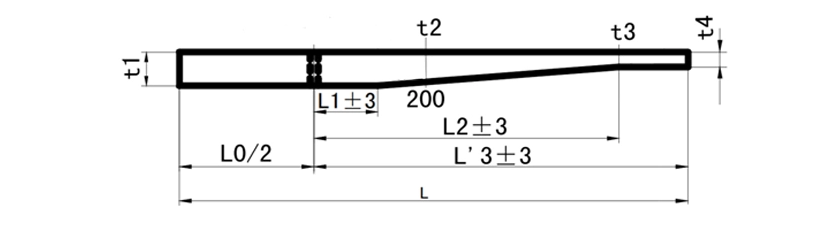

Njengoba kukhonjisiwe kuMfanekiso 1 ngezansi, ukulungiselelwa kwemingcele yeiqabunga spring rolling.

(Umdwebo 1. Imingcele egoqayo yentwasahlobo yeqabunga)

3.3.1. Izincazelo of rolling ukujiya

Ukujiya okungu-t1 ≥24mm, ukushisisa ngesithando somlilo esiphakathi.

Ukujiya kwe-Rolling T1<24mm, isithando somlilo sokugcina singakhethwa ukushisisa.

3. Izincazelo zezinto zokugingqa

Uma impahla injalo60Si2Mn, izinga lokushisa lokushisa lilawulwa ku-950-1000 ℃.

Uma impahla iyi-Sup9, izinga lokushisa lokushisa lilawulwa ku-900-950 ℃.

3.4. Ukugingqa futhiukusika iziphetho

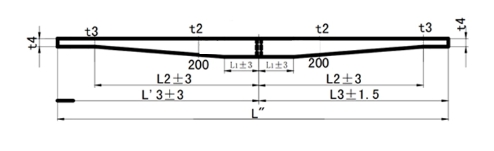

Njengoba kukhonjisiwe kuMfanekiso 2 ngezansi. Misa ingxenye engakwesokunxele yebha eyisicaba bese ugoqa uhlangothi olushisayo lwebha ngokwezidingo. Ngemuva kokuthi i-tapering ihlangabezane nezidingo zesayizi, usike isiphetho esifanele ngokusho kosayizi wokuklama. Ngokufanayo, ukugoqa nokuphela kokusika ngakwesobunxele ibha eyisicaba kuzokwenziwa. Imikhiqizo egoqwe emide idinga ukuqondiswa ngemuva kokugingqika.

(Umfanekiso 2. Imingcele yokunciphisa intwasahlobo yeqabunga)

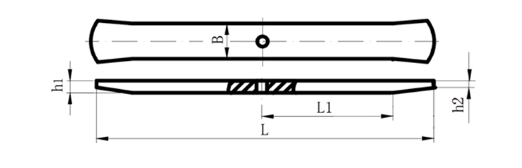

Uma kwenzeka ukuncipha kancane, uma ukunqunywa kokuphela kudingekile, futhi iziphetho kufanele zisikwe ngokuvumelana nendlela engenhla. Uma ukuphela kokuphela kungadingeki, iziphetho zentwasahlobo yamaqabunga zibukeka njenge-fan. Njengoba kukhonjisiwe kuMfanekiso 3 ngezansi.

(Umfanekiso 3. Imingcele emfishane yokuncipha kwentwasahlobo yeqabunga)

3.5. Ukuphathwa Kwempahla

Imikhiqizo yokugcina egoqiwe kufanele ipakishwe endaweni yokubeka impahla enendawo eqondile ebheke phansi, futhi uphawu lokuhlolwa losayizi abathathu (ubude, ububanzi nokuqina) luzokwenziwa, futhi ikhadi lokudlulisa umsebenzi lizonamathiselwa.

Akuvunyelwe ukujikijela imikhiqizo nxazonke, okubangela ukulimala kwendawo.

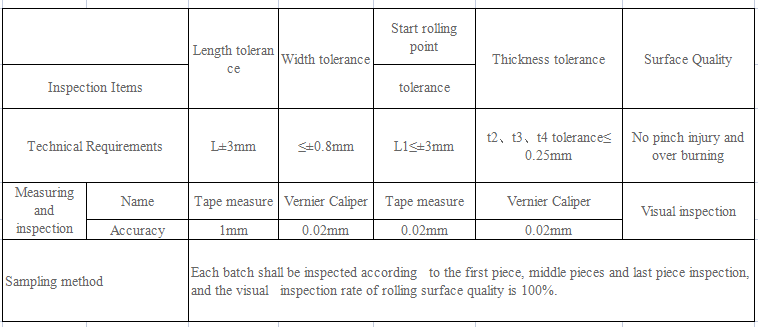

4. Izindinganiso zokuhlola (Bheka izinga: GBT 19844-2018 / ISO 18137: 2015 MOD Leaf Spring – Izicaciso Zobuchwepheshe)

Linganisa imikhiqizo eqediwe ngokomfanekiso 1 kanye noMfanekiso 2. Amazinga okuhlolwa kwemikhiqizo egoqiwe akhonjiswe kuThebula 1 ngezansi.

Isikhathi sokuthumela: Mar-27-2024